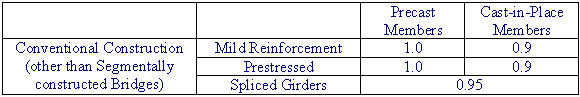

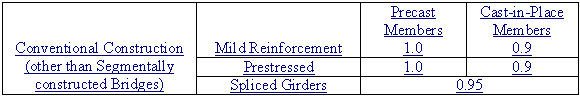

Article 5.5.4.2 of the AASHTO LRFD Bridge Design Specifications classifies concrete members as “prestressed” and “non-prestressed” and assigns resistance factors accordingly. This classification does not properly account for the difference in quality of workmanship between precast and cast-in-place construction. The quality of workmanship of cast-in-place post-tensioned construction does not compare to that of precast construction and, as such, does not warrant the same resistance factor. Concrete members will be classified as “precast” and “cast-in-place”. The following table summarizes the flexural resistance factors in tension-controlled concrete members. Flexural Resistance Factor for Tension-Controlled Concrete Members:

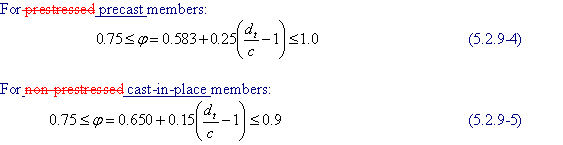

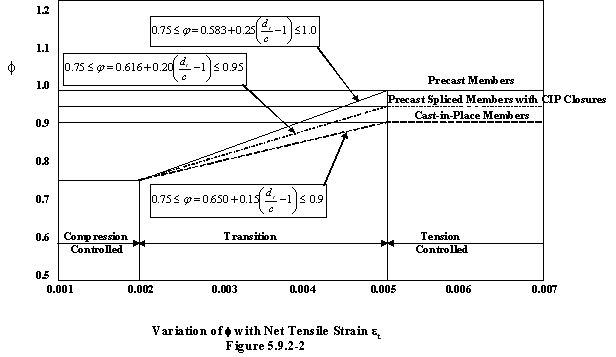

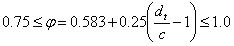

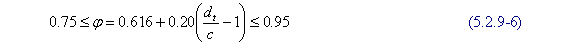

For compression-controlled members, regardless of the method of construction, the flexural resistance factor will continue to be taken as 0.75. For members in the transition zone between tension-controlled and compression-controlled, the flexural resistance factor shall be taken as follows: For precast members:

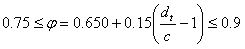

For cast-in-place members:

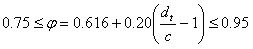

For precast spliced girders with cast-in-place closures:

For precast spliced girders with cast in-place closures the flexural resistance factor is taken 0.95 for strains greater than or equal to 0.005, and transition down to 0.75 for strains less than or equal to 0.002 This approach is very similar to the one taken for flexural resistance factor of Segmental Construction in Article 5.5.4.2.2. The flexural resistance factor for compression controlled members, regardless of the method of construction, continues to be taken as 0.75. This is due to the limited use of precast compression-controlled members in bridge construction. However, with increasing demand for precast compression members for accelerated bridge construction, the flexural resistance factor for compression controlled members may soon be revised.

Revise Article 5.2.9C-3 as follows:

Table 5.2.9-1 Flexural Resistance Factor for Tension-Controlled Concrete Members:

For compression-controlled members, regardless of the method of construction, the flexural resistance factor will continue to be taken as 0.75. For members in the transition zone between tension-controlled and compression-controlled, the flexural resistance factor shall be taken as follows:

For precast spliced girders with cast-in-place closures:

|