SUBJECT: Guidelines for Column Silos

WSDOT Bridge Design Manual Section 4.2.7 delineate that balanced stiffness and frame geometry recommended by AASHTO Guide Specifications for LRFD Seismic Bridge Design (SGS) Sections 4.1.2 and 4.1.3 are required for bridges in both SDCs C and D. Column silos are an acceptable technique to satisfy these requirements as described in SGS Section 4.1.4. This memorandum provides guidelines for design and detailing of column silos.

Due to the construction and inspection complications of column silos, designers are encouraged to meet balanced stiffness and frame geometry requirements by the other methods specified in SGS 4.1.4 for adjusting Dynamic Characteristics of the bridge, prior to use of column silos (column silos are to be used only as a last resort).

General Design and Detailing Requirements:

- Column silo plans, specifications and estimate shall be included in the Contract Documents.

-

- Column silos shall be designed to resist lateral earth and hydrostatic pressure, including live load surcharge if applicable, for a 75 years minimum service life.

-

- Column silos are not permitted for in-water locations such as in rivers and lakes.

-

- Clearance between the column and the column silo shall be adequate for column lateral displacement demands, construction and post-earthquake inspection but shall not be less than 1’-6”.

-

- A 6” minimum clearance shall be provided from the top of column silo to ground level.

-

- Maximum depth of column silos shall not exceed 15 feet.

-

- Column silos shall be watertight except at the top cover.

-

- Column silos shall be positively attached to the column foundation element.

Column Silos Formed From Extending Shaft Casing:

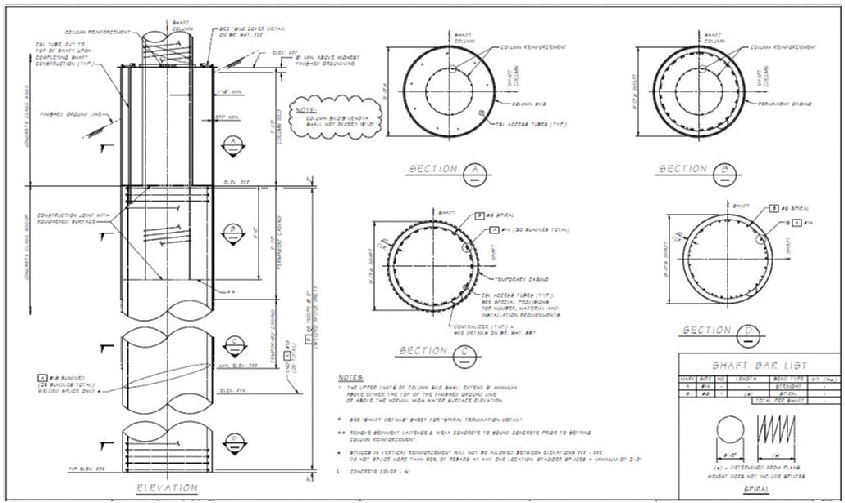

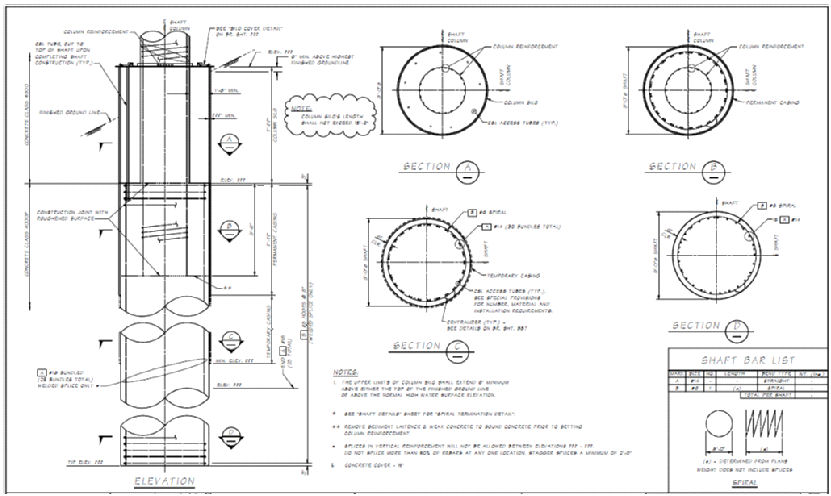

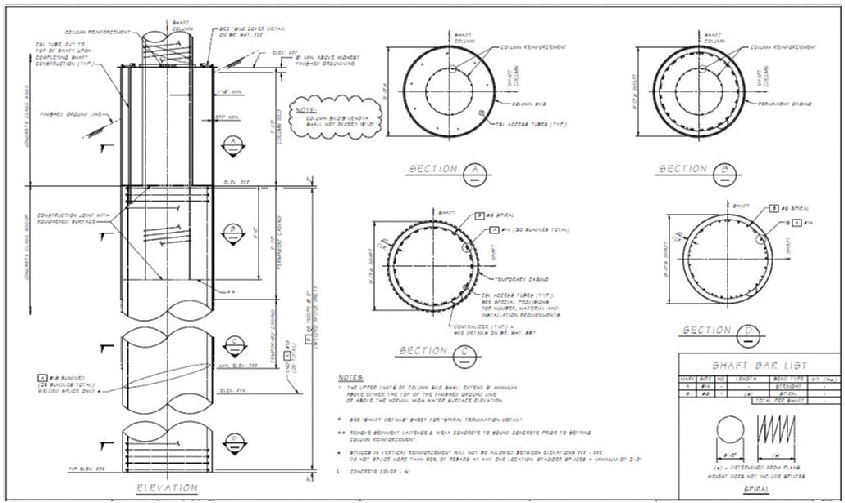

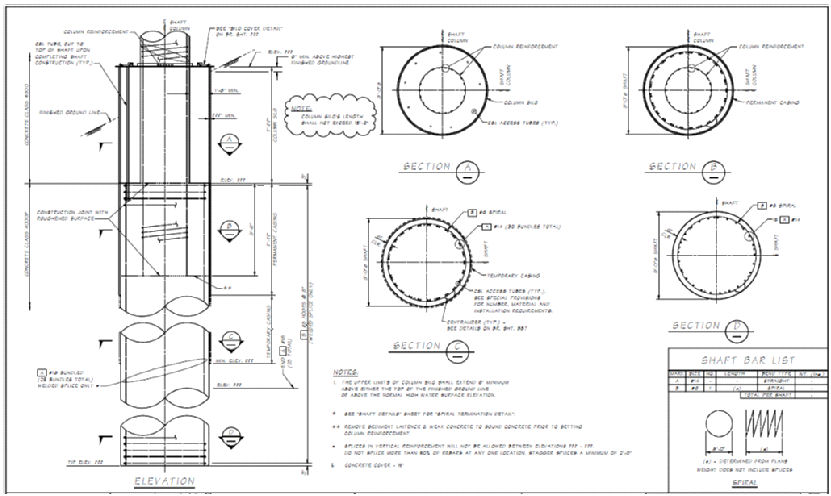

Designers shall determine a minimum steel casing thickness sufficient to resist lateral loads and shall provide it in the Contract Documents. This thickness shall include a sacrificial steel area as recommended in AASHTO LRFD Bridge Design Specification Section C10.7.5 for corrosion resistance. The actual steel casing size and materials shall be determined by the Contractor as delineated in WSDOT Standard Specification Sections 6-19 and 9-36. Appropriate detailing as shown in Figure 1 shall be provided.

Column Silos Formed By Other Methods:

Column silos formed by other methods, such as corrugated metal pipes, may be considered if the general requirements above are satisfied.

Column Silo Covers and Access Hatches:

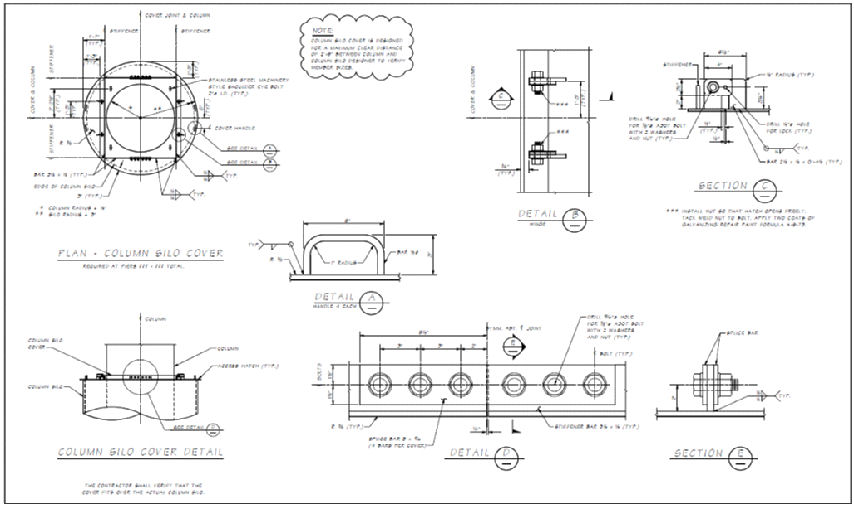

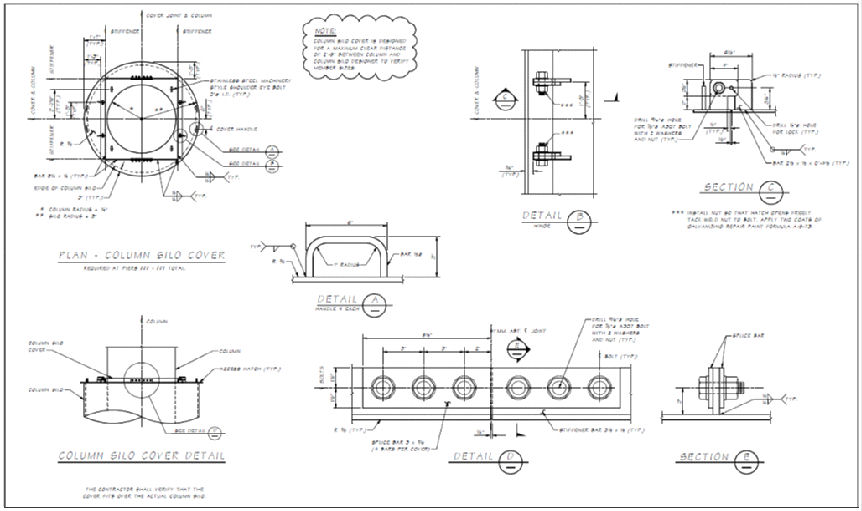

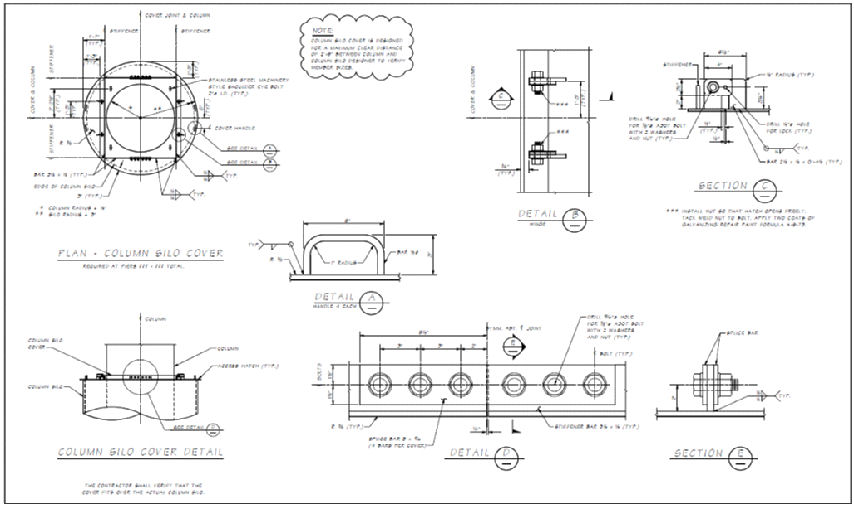

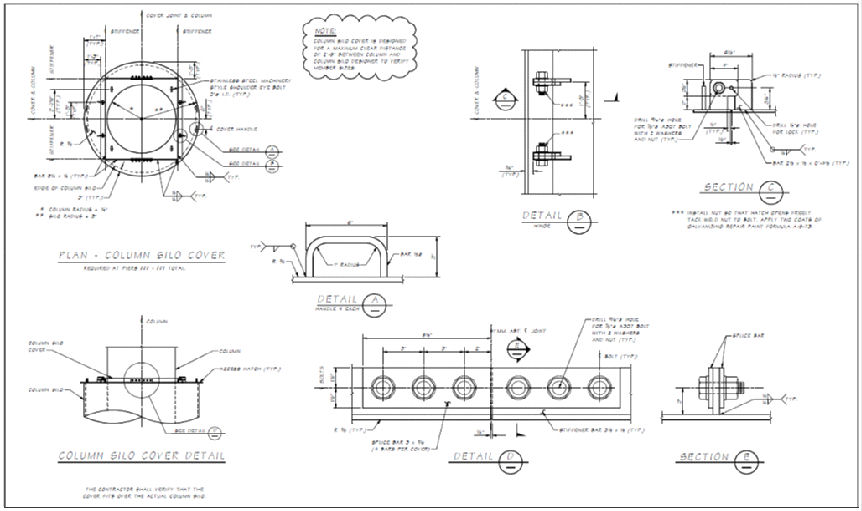

A column silo cover, including access hatches, shall be specified in the Contract Plans as shown in Figure 2. Column silo covers and access hatches shall be painted in accordance with WSDOT Standard Specifications Section 6-07.3(9).

Column silo covers shall be protected from vehicular loading. Column silo covers shall be capable of sliding on top of the column silo and shall not restrain column lateral displacement demands. Obstructions to the column silo cover sliding such as barriers or inclined slopes are not allowed adjacent to the column silo where they may interfere with column lateral displacement demands. Column silo covers and tops of column silos shall be level.

Sufficient access hatches shall be provided in the column silo cover so that all surfaces of the column and the column silo can be inspected. Access hatches shall include a minimum clear opening of 1’-0” x 1’-0” to accommodate the lowering of pumping and inspection equipment into the column silo. Access hatches for direct personnel access shall have a minimum clear opening of 2’-0” square. Column silo covers shall be designed to be removable by maintenance and inspection personnel. Public access into the column silo shall be prevented.

Background:

Column silos are one technique used to satisfy balanced stiffness and frame geometry requirements. However, the design requirements and detailing of column silos have not been standardized and a variety of column silos have been used for WSDOT bridges. This memorandum provides guidelines for design and detailing of column silos. The recommendations from the WSDOT AGC members on the constructability and suitability of proposed detailing for column silos have been incorporated in this memorandum.

If you have any questions regarding this memorandum please contact Brian Aldrich at 705-7224, Geoff Swett at 705-7157, Scott Sargent at 705-753, or Bijan Khaleghi at 360 705-7181.

cc: Mark Gaines, Bridge Construction - 47354

F. Posner, Bridge and Structures – 47340

Figure 1: Column Silos Casing Details

Figure 2: Column Silo Cover and Access Hatch Details

BDM Revision:

Chapter 7 Substructure Design

7.4.7-D Column Silos

Balanced stiffness and frame geometry are required for bridges in both SDCs C and D.

Column silos are an acceptable technique to satisfy these requirements as described in SGS Section 4.1.4. This memorandum provides guidelines for design and detailing of column silos.

Due to the construction and inspection complications of column silos, designers are encouraged to meet balanced stiffness and frame geometry requirements by the other methods specified in SGS 4.1.4 for adjusting Dynamic Characteristics of the bridge, prior to use of column silos (column silos are to be used only as a last resort).

General Design and Detailing Requirements:

- Column silo plans, specifications and estimate shall be included in the Contract Documents.

-

- Column silos shall be designed to resist lateral earth and hydrostatic pressure, including live load surcharge if applicable, for a 75 years minimum service life.

-

- Column silos are not permitted for in-water locations such as in rivers and lakes.

-

- Clearance between the column and the column silo shall be adequate for column lateral displacement demands, construction and post-earthquake inspection but shall not be less than 1’-6”.

-

- A 6” minimum clearance shall be provided from the top of column silo to ground level.

-

- Maximum depth of column silos shall not exceed 15 feet.

-

- Column silos shall be watertight except at the top cover.

-

- Column silos shall be positively attached to the column foundation element.

Column Silos Formed From Extending Shaft Casing:

Designers shall determine a minimum steel casing thickness sufficient to resist lateral loads and shall provide it in the Contract Documents. This thickness shall include a sacrificial steel area as recommended in AASHTO LRFD Bridge Design Specification Section C10.7.5 for corrosion resistance. The actual steel casing size and materials shall be determined by the Contractor as delineated in WSDOT Standard Specification Sections 6-19 and 9-36. Appropriate detailing as shown in Figure 1 shall be provided.

Column Silos Formed By Other Methods:

Column silos formed by other methods, such as corrugated metal pipes, may be considered if the general requirements above are satisfied.

Column Silo Covers and Access Hatches:

A column silo cover, including access hatches, shall be specified in the Contract Plans as shown in Figure 2. Column silo covers and access hatches shall be painted in accordance with WSDOT Standard Specifications Section 6-07.3(9).

Column silo covers shall be protected from vehicular loading. Column silo covers shall be capable of sliding on top of the column silo and shall not restrain column lateral displacement demands. Obstructions to the column silo cover sliding such as barriers or inclined slopes are not allowed adjacent to the column silo where they may interfere with column lateral displacement demands. Column silo covers and tops of column silos shall be level.

Sufficient access hatches shall be provided in the column silo cover so that all surfaces of the column and the column silo can be inspected. Access hatches shall include a minimum clear opening of 1’-0” x 1’-0” to accommodate the lowering of pumping and inspection equipment into the column silo. Access hatches for direct personnel access shall have a minimum clear opening of 2’-0” square. Column silo covers shall be designed to be removable by maintenance and inspection personnel. Public access into the column silo shall be prevented.

Figure 1: Column Silos Casing Details

Figure 2: Column Silos Casing Cover and Access Hatch Details

Note: Click here for a PDF of this design memo.